By Anđela Martinović, Ph.D., Owen Zammit, Orly Savion, Ph.D., & Eva Everloo – Investment Team at PeakBridge

Fermentation is one of the oldest biotechnological methods used in food production. The most widely used products obtained by fermentation include yogurt, cheese, tempeh, sauerkraut, beer, and wine. Fermentation is a process performed by microorganisms – tiny living entities such as bacteria and yeasts that mostly use sugars for energy production. Traditionally, fermentation has been used to enhance the nutritional and functional characteristics of food, improve sensorial properties, and remove toxins and food-borne pathogens.

Precision fermentation is considered an advanced type of fermentation that is used to produce certain vitamins and antioxidants (food supplements), rennet (cheesemaking), or human drugs such as insulin. Today, precision fermentation is also applied to obtain a variety of new-generation products. Examples include dairy, meat and egg alternatives, alternative oils and fats, and novel pet food – all of which are produced as a sustainable, animal-free, sometimes more nutritious alternative to their traditional counterparts.

A recent article published by The Guardian describes precision fermentation as “what may be the most important green technology ever.”, indicating that this technology could even “produce new staple foods and end our reliance on farming.” Hence, food multinationals are exploring the benefits of precision fermentation for their product portfolio. For example, Unilever has decided to investigate the use of precision fermentation to reinvent their ice creams, and Nestlé recently announced their partnership with precision fermentation company Perfect Day to pilot a new dairy milk alternative.

Considering the growing number of startups using precision fermentation and our commitment as PeakBridge to identify unmet needs in FoodTech and stay on top of emerging developments, in this blog, we will dive deep into precision fermentation, addressing its key applications, advantages, and challenges, concluding with the current startup landscape. This is the 5th installment in the series — following our recent Personalized Nutrition review, which you can find here.

THE BASICS

Fermentation types

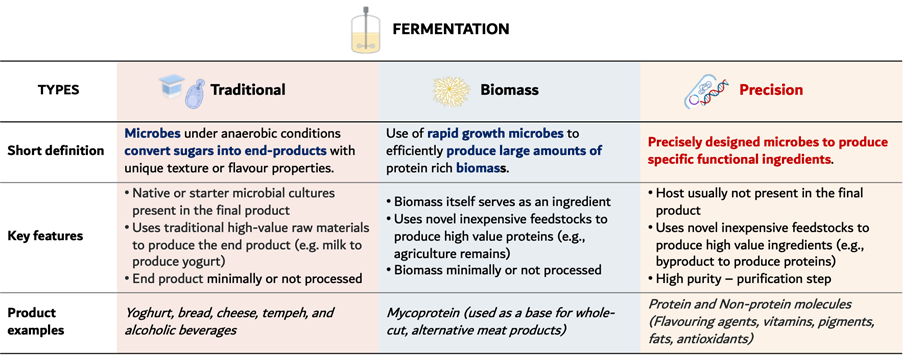

Three main types of fermentation are used by the food industry: traditional, biomass, and precision fermentation. The definitions and main features are given in Figure 1 below.

All three fermentation types can be performed through two distinct approaches: submerged (SmF) and solid-state fermentation (SSF). SmF requires microorganism growth in a liquid medium, whilst SSF occurs through growth on a solid substrate. Both approaches have pros and cons in terms of yields, scalability, energy use and CAPEX. The approach will usually be selected based on properties that are required in the final product.

Depending on the type of microorganism used, fermentation can also be categorized as aerobic (requiring oxygen) or anaerobic (not requiring oxygen). Aerobic fermentation tends to have higher yields and lower toxic byproducts yet might require a constant supply of oxygen which can be expensive. Anaerobic fermentation’s lack of oxygen supply can make it more cost-effective, yet it produces methane and other greenhouse gases as byproducts, making it less environmentally friendly.

HOW IS IT DONE?

Precision fermentation involves a microbial host that is used as a fermentation “factory” to obtain a target ingredient. Examples of a target include a particular protein (e.g., casein, heme), flavoring agent, vitamin, pigment, and lipid. This is done by genetic modifications affecting the host’s DNA, e.g., through the introduction of foreign DNA. Several techniques can be used, including genome modification and genome editing (CRISPR-Cas9).

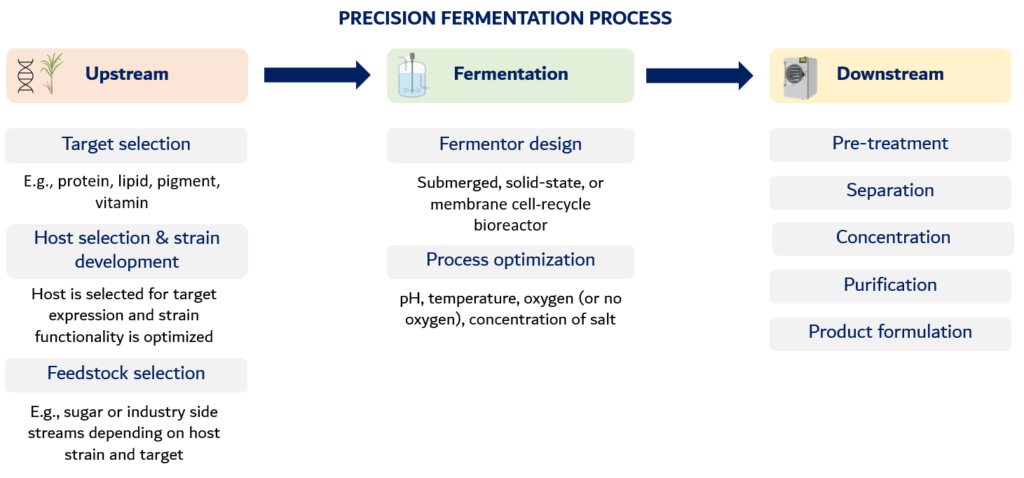

The precision fermentation process can be divided into three phases: upstream, (actual) fermentation, and product-specific downstream (Figure 2).

Figure 2. Precision fermentation processing steps

This process is costly, labor intensive, and requires specialized expertise. For each step of the process, there are multiple considerations and parameters that can be optimized to impact key aspects such as target product taste, quality, cost, and scalability. Main steps of the upstream and fermentation process are addressed below.

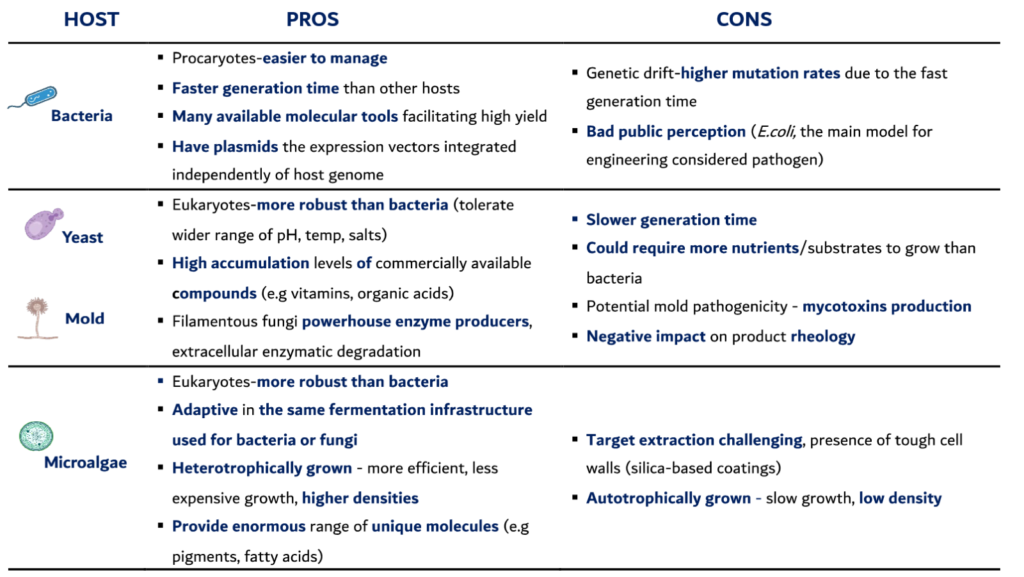

TARGET & HOST SELECTION

The precision fermentation process starts with the selection of a target product. For this process, one or more host microorganisms are required. The host is selected for its ability to express the desired target, cost-effectiveness, downstream processing complexity, and more. See Table 1 below for host types and their pros and cons.

Advantages and disadvantages of host types used in precision fermentation

Recent advancements in high-throughput – omics (e.g., proteomics, metabolomics) have increased our understanding of metabolic pathways under different environmental conditions that are used for strain development. These advancements simplified the ability to genetically manipulate the host and increased the efficiency and cost-effectiveness of precision fermentation as a process. Examples of how efficient and targeted strain development can affect the precision fermentation process:

- Usage of inexpensive feedstock vs. complex raw materials (e.g., byproducts of different industries or waste).

- Improved energy and resource efficiency (e.g., reduce the need for cooling/heating, water, and nutrient consumption).

- Shortening of fermentation time cycles.

- Increased yield of target product(s).

- Simplified downstream processing (e.g., extraction of target ingredient to media, impurities, or undesirable by-products reduction).

- Better product recovery.

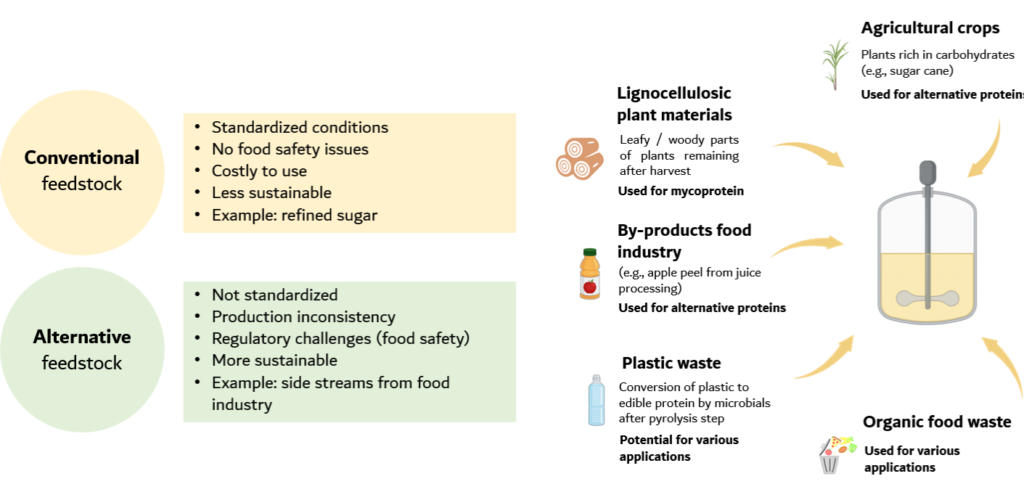

FEEDSTOCK SELECTION

Feedstock composition is a large cost, quality and environmental impact driver for precision fermentation, affecting process efficiency, target properties and process sustainability. See Figure 3 for characteristics of conventional and feedstock alternatives (left) and examples (right).

Characteristics (left) and examples (right) of conventional and alternative feedstock options

Fermentor Design

Fermentors are bioreactors selected for their ability to meet the specific requirements of the fermentation process. This is – among others – dependent on the target product, the host, the fermentation method (submerged or solid-state fermentation) and the type of feedstock used.

Process optimization

Besides oxygen supply (or a lack hereof), there are other process parameters that are important determinants of the precision fermentation process, affecting costs, scalability, and target outcomes. These include temperature, pH, and concentration of salt. Furthermore, as precision fermentation is an energy-intensive process, the source of energy (fossil fuel vs. clean energy) has a significant impact on the LCA of the process.

Scale of precision fermentation

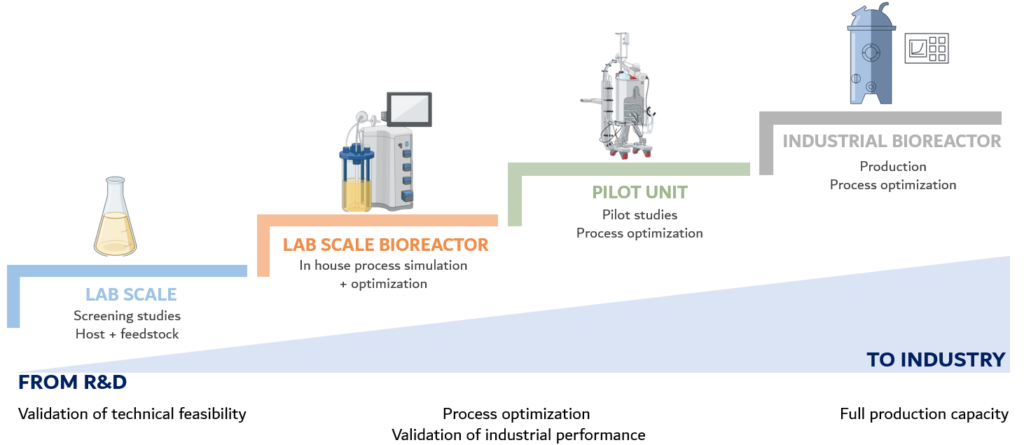

Precision fermentation requires intensive R&D preparation, starting from the genetic altering and optimization of the host, followed by feedstock selection and preparation and downstream process design that will result in the high standards of the final target product. Those initial steps are done on a small laboratory scale (single tens of milliliters) and are gradually scaled up as described below (Figure 4) to reach its full industrial scale (up to tens of thousands of liters).

Steps of scaling up process

KEY APPLICATIONS

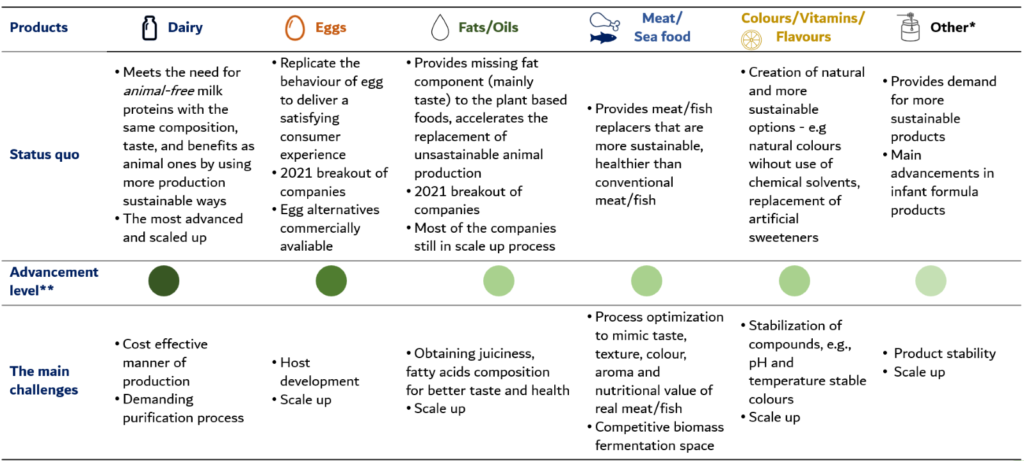

Precision fermentation can be used for numerous target products. See Table 2 below for the areas that are currently undergoing key innovation.

Applications of precision fermentation, produced targets according to product type

*Other: high value targets produced in a cost-efficient and sustainable production with stabilized supply chain, such as pet food, bee-free honey, collagen, and infant formula.

**Advancement level: the darker the color, the more advanced the application is, considering scale, commercial availability, and number of currently existing companies.

WHY NOW

With a growing world population to feed, severe climate changes, and the reduction of fertile lands to grow our food, the demand for more efficient, sustainable, and arable land-free food production is clear. Recent progress in bioinformatics, biotechnology, and AI tools, combined with the ability to construct sophisticated large-scale fermenters, has made precision fermentation one of the most promising tools for future food manufacturing. That is, provided that the process relies on clean energy and can use alternative feedstock, such as industry side-streams that do not require substantial use of arable lands (as opposed to the refined currently used feedstock).

Precision fermentation joins the list of alternative food technologies (e.g., plant-based and cell-based methods) in producing alternative, sustainable ingredients. However, it fills the gap that these technologies leave behind: enabling the production of high-level, functional products at high yields and purity with an extremely low environmental footprint. Specifically compared to plant-based methods, precision fermentation is able to overcome major taste and texture challenges. In addition, it also has the potential to overcome cost-parity challenges related to cell-based methods available today.

Key incentives for precision fermentation:

- Need for technologies with lower environmental footprint.

- Food security (e.g., global protein availability).

- Animal welfare concerns and demand for animal-free food.

- Consumer demand for sustainable alternatives with taste and texture mimicking that of their conventional counterparts.

- Transformative potential of molecules using precisely developed microbes to develop next-generation proteins, fats, and more.

Main advantages:

- Lower demand for inputs, energy, land, and water compared to animal products.

- Possibility for local and circular solutions (e.g., use of local feedstock).

- Highly customizable product characteristics allow for more sustainable and healthy products (highly nutritious, low waste, no antibiotics, no allergens, etc.).

Disadvantages:

- Public negative perception of unnatural/genetically modified foods.

- Potential production of toxic waste in the process.

- Large capital required for custom fermentors, limiting industry growth.

- Current high product prices due to the early phase of tech.

CHALLENGES

Before precision fermentation reaches the desired scale to serve our global food systems, the following challenges ought to be overcome:

R&D acceleration:

- Strain selection and modification to optimize functionality, performance, and cost-effectiveness.

- To find a long-term sustainable carbon source as input for precision fermentation. (e.g., waste and industry side-streams).

Process scalability: large investments and techno-economic analyses are needed.

- It is forecasted that demand for alternative proteins alone will require three orders of magnitude more fermentation capacity than is currently available by 2030.

- To reach the desired scale, the technology needs to be adopted at a corporate level.

- Analyses need to assess overall economic viability during scale-up and identify critical factors determining the cost of the targeted molecule(s), LCAs, etc.

Suitable fermentor designs:

- In addition to the general global shortage of fermentor devices, tailored fermentation designs might be required (e.g., some existing fermentation infrastructure is constructed for anaerobic bioethanol production, unsuitable for precision fermentation).

Education:

- Both for operators, scientists, and engineers experienced in precision fermentation manufacturing and scale-up, as well as for consumers to increase acceptance of GM products.

Regulation:

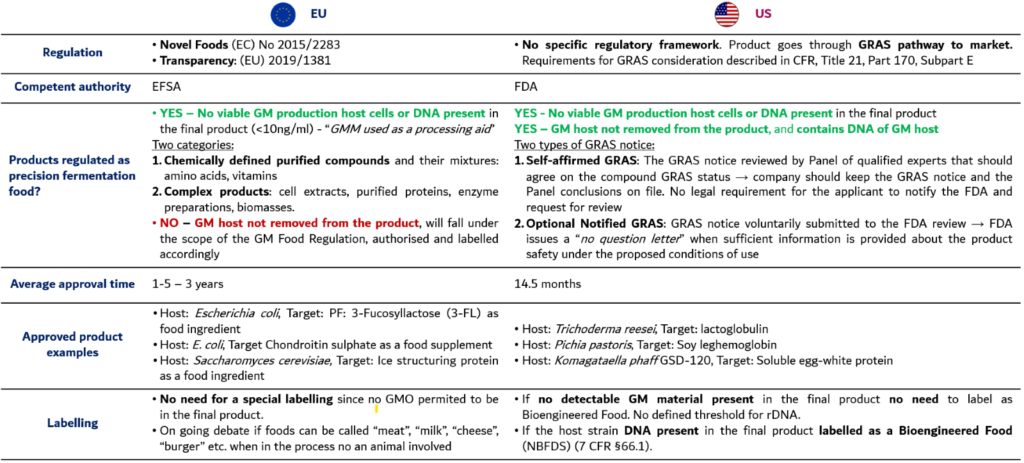

- Convince regulatory authorities of product safety and quality. Most critical concerns: safety of host strain and purification of the target product. See Table 3 below for a summary of the regulative requirements for the EU (left) and US (right).

Table 3. Comparison between European (EU) and United States (US) precision fermentation regulations

EFSA: The European Food Safety Authority; FDA: U.S. Food and Drug Administration; GRAS: Generally Recognised as Safe; GM: genetically modified; CFR: Code of Federal Regulations.

STARTUP LANDSCAPE

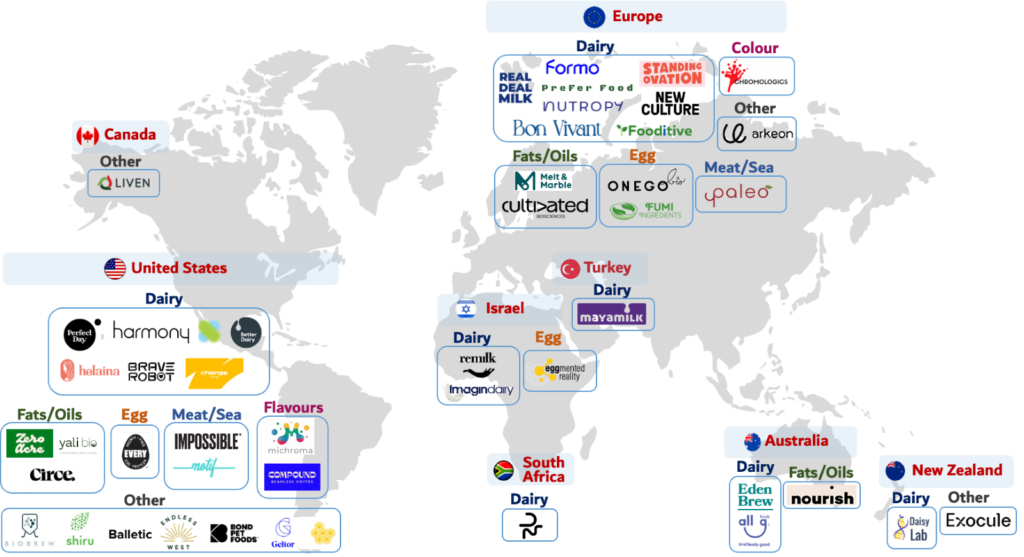

The industry has seen a recent wave of startups working on various precision fermentation products. Alternative proteins (dairy in particular), alternative fats, oils, seafood, and other functional ingredients are especially high in development. However, there are also more niche categories, such as alternative pigments, chocolate, spirits, and honey! In 2021, investments in precision fermentation solutions globally exceeded $750M, a record for the industry. In 2022, the market for precision fermentation will have an estimated size of $1.6B and is expected to grow to $36B by 2030. See Figure 5 below for the geographical spread of examples of key players that are leading in this space. PeakBridge invested in ImaginDairy (IL) and Standing Ovation (FR), which work on creating animal-free dairy and cheese proteins, respectively.

Map showing precision fermentation startups around the world

KEY TAKEAWAYS

The objective of fermentation is to reimagine traditional foods by creating more sustainable, healthier, and/or more appealing alternatives using microbes. This deep dive touched on the various components of the precision fermentation process – a technology that is rapidly being adopted by FoodTech companies. Innovation in this space is reflected mostly in dairy applications, as well as oils, fats, eggs, meat, and seafood. And it does not stop there – the opportunities are enormous.

The power of precision fermentation lies in its precise, controlled production of functionally identical ingredients that overcome the taste and texture barriers of plant-based food products. The technology enables food producers to efficiently create specific proteins, lipids, vitamins, enzymes, pigments and more using microbes instead of animals. Given the right inputs, precision fermentation can be presented as one of the most promising tools for reducing our food systems’ environmental impact. However, key challenges remain, especially those pertaining to strain development, alternative feedstock for sustainability, process scalability, proper infrastructure, consumer education, and regulation. Can these challenges be overcome in the coming years?

All in all, it is clear that significant investment combined with partnerships in the food sector will lead to accelerated integration of precision fermentation. And for that reason, we expect to see rapid progress in the upcoming years.

SELECTED FURTHER READING

Chai, Kong F., et al. “Precision fermentation to advance fungal food fermentations.” Current Opinion in Food Science 47 (2022): 100881.

Foodhack. Precision fermentation: The 40+ Companies Using Microbes To Re-Create Our Favorite Foods, 2022: https://foodhack.global/articles/Precision-Fermentation-New-Developments

Good Food Institute. State of the Industry Report: Fermentation, 2021: https://gfi.org/resource/fermentation-state-of-the-industry-report/#startups

ProVeg incubator. Precision fermentation regulation. 2022: https://provegincubator.com/precision-fermentation-regulation/

Sanghavi, Gaurav, et al. “Microbial Strain Engineering.” Engineering of Microbial Biosynthetic Pathways. Springer, Singapore, 2020. 11-32.

Takefuji, Yoshiyasu. “Sustainable protein alternatives.” Trends in Food Science & Technology 107 (2021): 429-431.

Teng, Ting Shien, et al. “Fermentation for future food systems: Precision fermentation can complement the scope and applications of traditional fermentation.” EMBO reports 22.5 (2021): e52680.